Investments

Trasteel Group invests into strategic industrial and services targets in order to generate captive flows and consolidate its trading activity

Trasteel grew exponentially since its birth in 2009. The ability to seek market opportunities and catch the right moment is surely an important characteristic of the management. It is important to avoid being static by diversifying and expanding into broaden sectors, step by step. Despite its growth, the Group is strongly attached to its core values: the care of its people and its authentic and familiar approach to business.

The main investments of Trasteel are in the steel transformation sector, which is the segment of the steel value chain where the trading skills have a major importance.

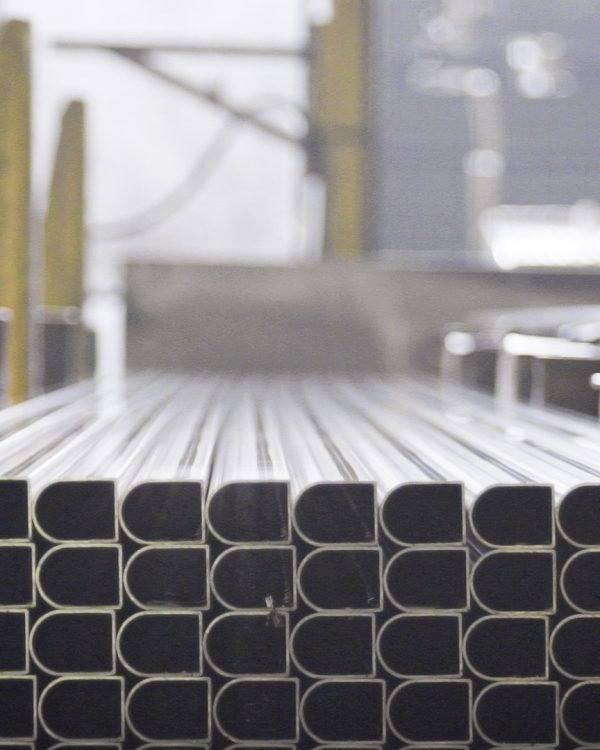

Profilmec S.p.A.

Located in Torino, Profilmec S.p.A. is one of the companies of PROFILMEC GROUP and its core business relates production of precision High Frequency (HF) welded steel tubes and profile sections.

The materials used are pickled, coldrolled, aluminized and galvanized.

It boasts a modern and functional organization that operates within a sales network in Italy and the rest of Europe. The history of PROFILMEC GROUP has its roots set within the last 50 years, and Profilmec S.p.A. itself has an impressive impact of the Group growth with up to 150.000MT of pipes produced per year.

Ispadue S.p.A.

Ispadue S.p.A. is located in  Pordenone and it is one of the main realities of the PROFILMEC GROUP with a total production up to 150.000MT of pipes per year.

Pordenone and it is one of the main realities of the PROFILMEC GROUP with a total production up to 150.000MT of pipes per year.

The peculiarity of this premise is that cold rolling, hydrogen annealing in EBNER furnaces and surface rolling facilities make it possible to reroll coils with various characteristics.

These can be personalized upon request (for mechanical characteristics, surface finish, complex galvanic treatments, narrow and asymmetric tolerances on thicknesses). Small lots can be provided within short waiting time for those market niches not serviced by large steelworks.

LIFI S.r.l.

LIFI S.r.l. is situated in the province of Torino and it specializes in the production of precision steel tubes, cold-formed and high-frequency welded tubes made from hot-rolled, pickled, cold-rolled and coated, for a total production of 8.000MT per year.

LIFI S.r.l. is situated in the province of Torino and it specializes in the production of precision steel tubes, cold-formed and high-frequency welded tubes made from hot-rolled, pickled, cold-rolled and coated, for a total production of 8.000MT per year.

Its multifunctional production facility in Lombardore (TO) is equipped with cutting-edge CO2 and fiber lasers for custom cutting and processing of high-strength and ultra-highstrength steel tubes.

ROLM S.r.l.

ROLM S.r.l. specializes in the design, manufacture and installation of high-tech machines for tube production and sheet metal processing.

ROLM S.r.l. specializes in the design, manufacture and installation of high-tech machines for tube production and sheet metal processing.

It is located in a 4.000 square-meter warehouse in Cavallerleone (CN), very close to Torino. It has available a large fleet of used and overhauled machines, the used lines are reconditioned to new in the mechanical, electrical, hydraulic and pneumatic components.

CMP S.r.l.

CMP S.r.l. is located in Torino, and is part of the Profilmec Group, being its commercial division.

SIM S.r.l.

Based in Teramo, Italy, SIM S.r.l. is a company focused on the production of steel pipes and cut-to-length pipes. It is owned by both Profilmec Group (50%) and the renowned Italian company Marcegaglia (50%).

Yugotub d.o.o.

Yugotub d.o.o. is located in Serbia, Belgrade.

With a floor area of 7.000 square-meter, it runs three machines for the welded tubes production, one slitter for cutting coils into narrow strips, and three cutting machines for cutting tubes to length.

Product range includes tubes of round, square, rectangular, semi-oval, octagonal, oval and special sections, as per the customer requirements. The tubes can be made in commercial bars up to 8000 mm length, and can be cutsized and specially packed.

Materials used for production are cold rolled and pickled steel coils.

Yugotub is a company certified according to ISO 9001:2015 and ISO 14001, and tubes are produced in conformance with EN 10305-3:2002 and EN 10305-5: 2003 standards.

Officine Tecnosider S.r.l.

Officine Tecnosider is a steel rerolling plant.

Officine Tecnosider is a steel rerolling plant.

It was created as a greenfield project in 2009 with Trasteel owning initially 30%, which became 51% in 2020, while 49% is today owned by the international leading steel trader Vanomet.

Its production capacity is 400,000 metric tons/year of plates and round bars with a broad range of products customers as per specifications.

The range of steel of Officine Tecnosider will encompass all the standard structural grades, boiler steel, steel for quenching & tempering and steel for pressure vessels.

The company started production in 2011 and reached already full capacity after less than one year. The Company is able to comply with customers specific requests according to any range of analysis certified by international standard.

The company’ steel operations are established in San Giorgio di Nogaro (Udine), in a strategic location close to two main ports and to the main European customers.

TAMAC S.r.l.

TAMAC S.r.l. is a steel service center located in Massa (Italy) focused on cutting to size of cold rolled, hot rolled and coated flat sheet metal.

A Just-in-Time service ensures the finished product’s delivery to Italy, Europe and northern Africa countries.

With a production capacity of 120,000 MT/year, Tamac stores more than 20,000 MT of coils in its own 10,000 sqm heated warehouse, processing shims from 0.6 mm up to 8.0 mm.

The Trasteel International support ensures hot and cold rolled, and coated flat sheet metal coils sourced from the world’s leading steel mills, allowing Tamac to offer high quality products at a very competitive price. To guarantee high standard performances, every item is checked in a dedicated control area.

Tamac supplies products to a wide range of industries, including automotive, white goods, commercial and agricultural vehicles, lighting systems, plumbing, building, conditioning and household appliances.

Yingkou Liangyu Trasteel Refractory Co. Ltd

Trasteel owns a stake in one of China’s leading manufacturers of Magnesia-Carbon and Alumina-Magnesia-Carbon refractory bricks, in a Joint Venture under the name “Yingkou Liangyu – Trasteel Refractory Co. Ltd.”.

Trasteel is its exclusive marketing arm, handling marketing, sales, production financing and technology advancement.

The JV integrates manufacturing and research facilities, producing, with a capacity of about 70’000 MT/year, the following range of products:

- Magnesia Carbon bricks for converters, electric arc furnaces and ladles

- Magnesia Alumina Carbon bricks

- Alumina Silicon Carbide bricks

- Fired Magnesia and Fired Magnesia Chrome and Spinel Bricks

- Sliding Gate Plates and Nozzles for Tundish and Ladle flow control

- Unshaped products for lining installations and maintenance of steel making units

Trasteel partner owns a mine with uncovered deposits of raw magnesite of 30 million MT, with an annual output of 200,000 MT, assuring to the JV a competitive source of fused and sintered Magnesia raw materials.

Trasteel Engineering Polska sp.zo.o & Trasteel Inginerie S.r.l.

The two companies were set up in 2015 and produce, cut and bend steel, assembling structures based on client specifications and metalworks for fabrications.

The two companies were set up in 2015 and produce, cut and bend steel, assembling structures based on client specifications and metalworks for fabrications.

They are active in the shaping and assembling rebar production for reinforced concrete in Poland/Romania and the rest of Europe, and metal works for civil and tunnel constructions.

The two production units are situated in Warsaw (Poland) and Galati (Romania).

Clients are the main construction companies acting in the large-scale infrastructure, civil and industrial engineering. After years of experience by their shareholders, the Companies established a close relationship with their customers becoming a full service providers.

In addition, the companies benefits from the network and know-how of a well-established Polish company active since 2015. As well for the Romanian market, where the company invested in the country’s development, entering the market for producing cut and bend, steel cages automatically assembled, and other services provided by its qualified staff. Actually Trasteel Engineering Polska owns 100% of Trasteel Inginerie.

In addition, the companies benefits from the network and know-how of a well-established Polish company active since 2015. As well for the Romanian market, where the company invested in the country’s development, entering the market for producing cut and bend, steel cages automatically assembled, and other services provided by its qualified staff. Actually Trasteel Engineering Polska owns 100% of Trasteel Inginerie.

Trasteel Makina ve Ticaret A.S. / Fematek

Trasteel Makina ve Ticaret A.S. produces a broad range of heavy carpentry products to satisfy various commercial and industrial requirements.

Its highly skilled personnel, with over two decades of experience with the major OEMs, and an impressive reference list, guarantees the most competitive lead times, quality and prices with European and Asian suppliers.

Based in Istanbul and Izmir, it is strategically located for logistics, with connections by sea or truck to Europe, Middle East and North Africa.

UTIL Industries S.p.A.

Since its foundation in 1959, UTIL has rapidly established itself as a reference company for the production of components for automotive braking systems, achieving a significant market share globally. Today UTIL is present in Italy and China with production plants and research centers and in Germany and the United States with a sales representation.

Headquarters of the UTIL Group and headquarters of Util Industries, the Villanova d’Asti (AT) site has the latest technologies and presses, operating in a power range of 630 to 1,400 tons, to meet the most complex market demands.

Util (Guangzhou) Auto Parts Co. Ltd, which has a new 10,000 m2 facility in the Nansha district, provides state-of-the-art technology and efficient production processes such as fine blanking, single and progressive stamping, brushing and polishing to serve Asian markets, with a focus on the automotive sector.